Introduction: How to Generate Gerber Files From Eagle 9

In this instructable I'm gonna show you how you can generate gerber files from Eagle CAD version 9 and above and how to order your PCBs using the gerber files.

- The Gerber format is an open ASCII vector format for printed circuit board (PCB) designs. It is the de facto standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill data, etc.

- Launch a.pcb file, or any other file on your PC, by double-clicking it. If your file associations are set up correctly, the application that's meant to open your.pcb file will open it. It's possible you may need to download or purchase the correct application.

- Open the CAM Processor. In Eagle, open Board view. Click the 'CAM' button or choose 'File-CAM.

Package Gerber File. Altium saves all generated Gerber and NC Drill files in the 'Project output folder', usually it is in the same folder as your PCB project folder. Rename the project output folder to something meaningful so you know what it is. Then zip all files in the output folder and send to us for PCB fabrication.

Step 1: Watch the Video!

The video describes the process of generating gerber files using EagleCad and provides info how to use my CAM processor file that will automate the process for you. The are subtle things which are present in the video that we're left out from this instructable for the sake of simplicity.

Step 2: The CAM Processor

How To Open Pcb Gerber File System

The actual start might depend on the cad software that you use for designing pcb's, in my case that's Eagle Cad. After finishing up the design of a PCB, you will have to generate the gerber files needed to place your order. Think at these as an universal set of files, stored in a format that every pcb manufacturing facility can read and use to manufacture your pcb exactly as you designed it.

In Eagle CAD we have the CAM processor that takes care of these things, and luckily you can just load a pre-made CAM job file, that will instruct eagle how to output a complete set of gerber files. I have a custom made, voltlog CAM job file for 2 layer pcbs, Here is a link that you can use to download it.

This cam job file will generate all the required gerber files for ordering your pcb, including files for the cream layer which can be used to order a steel stencil that will make assembly of surface mount components much easier. Just click process job and save the resulting zip archive.

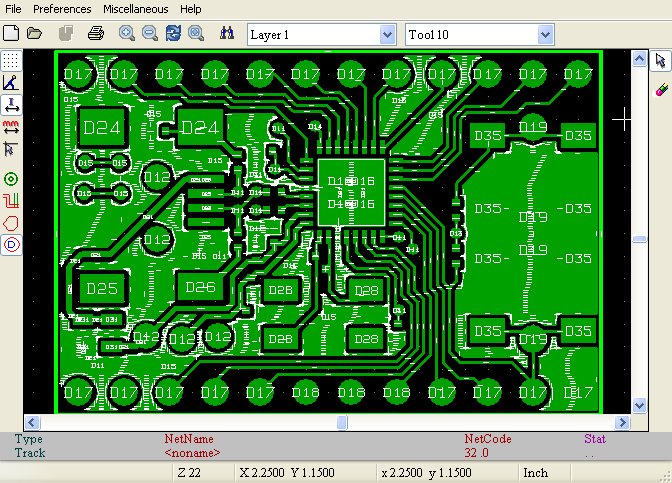

Step 3: Verifying the Gerber Files

It's a good idea to now check your gerber files to see if they look like you want them to look. I often catch problems in the gerber files, things that we're too small to notice in the pcb layout software. There are a bunch of different website where you can view gerber files online and also a whole set of programs which you can use to do that locally on your computer. Here is one example of an online gerber viewer.

Step 4: Order Your PCB

- The Gerber format is an open ASCII vector format for printed circuit board (PCB) designs. It is the de facto standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill data, etc.

- Launch a.pcb file, or any other file on your PC, by double-clicking it. If your file associations are set up correctly, the application that's meant to open your.pcb file will open it. It's possible you may need to download or purchase the correct application.

- Open the CAM Processor. In Eagle, open Board view. Click the 'CAM' button or choose 'File-CAM.

Package Gerber File. Altium saves all generated Gerber and NC Drill files in the 'Project output folder', usually it is in the same folder as your PCB project folder. Rename the project output folder to something meaningful so you know what it is. Then zip all files in the output folder and send to us for PCB fabrication.

Step 1: Watch the Video!

The video describes the process of generating gerber files using EagleCad and provides info how to use my CAM processor file that will automate the process for you. The are subtle things which are present in the video that we're left out from this instructable for the sake of simplicity.

Step 2: The CAM Processor

How To Open Pcb Gerber File System

The actual start might depend on the cad software that you use for designing pcb's, in my case that's Eagle Cad. After finishing up the design of a PCB, you will have to generate the gerber files needed to place your order. Think at these as an universal set of files, stored in a format that every pcb manufacturing facility can read and use to manufacture your pcb exactly as you designed it.

In Eagle CAD we have the CAM processor that takes care of these things, and luckily you can just load a pre-made CAM job file, that will instruct eagle how to output a complete set of gerber files. I have a custom made, voltlog CAM job file for 2 layer pcbs, Here is a link that you can use to download it.

This cam job file will generate all the required gerber files for ordering your pcb, including files for the cream layer which can be used to order a steel stencil that will make assembly of surface mount components much easier. Just click process job and save the resulting zip archive.

Step 3: Verifying the Gerber Files

It's a good idea to now check your gerber files to see if they look like you want them to look. I often catch problems in the gerber files, things that we're too small to notice in the pcb layout software. There are a bunch of different website where you can view gerber files online and also a whole set of programs which you can use to do that locally on your computer. Here is one example of an online gerber viewer.

Step 4: Order Your PCB

The next step is to send these files to the pcb fab house and the service I use is JLCPCB.com, they really offer cheap pcbs so ofcourse I'm using their service. At a cost of $2 for a set of 10 pcbs and $6 for a laser cut steel stencil, I don't think you can find cheaper.

Gameshark ps2 iso. The ordering process is as simple as uploading the zip archive with the gerber files we created earlier to their website and going with the default settings. If you are a more advanced user you might play with the settings for getting a different thickness or a different soldermask color for example, but for a beginner, the defaults are good enough and depending on which shipping method you choose in a week (for DHL) you should have the PCBs at your door.

So, that was all, I hope this instructable was useful if so please leave a comment or hit the like or dislike button to send me some feedback.

Be the First to Share

Recommendations

How To Open Pcb Gerber File Download

Make it Glow Contest

First Time Author Contest

PCB Challenge